Rigid Flex PCB is a high-density interconnect product that combines the characteristics of rigid and flexible circuit boards, widely used in high-end electronic devices such as smartphones, medical equipment, aerospace instruments, etc. Its 10 layer structure achieves high integration and flexibility by alternately stacking hard and soft boards, but the production process is complex, involving precision machining and strict quality control. The following analysis will focus on structural design, process flow, production control points, and technical difficulties.

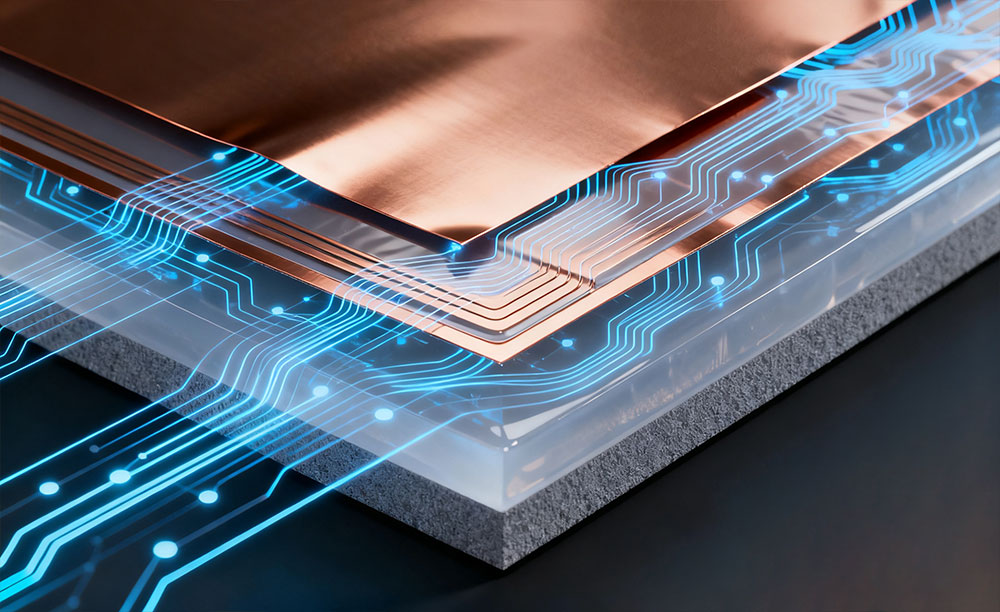

The substrate of a regular rigid PCB is tightly bonded to copper foil, while the surface of the P substrate of FPC is smooth and requires special treatment to ensure that the copper foil adheres firmly. During pretreatment, the P1 film is first etched with a chemical solution (such as sodium hydroxide) to create tiny pits, then coated with a layer of adhesion promoter (similar to "glue"), and finally bonded to the substrate through hot pressing. An experiment conducted by a certain FPC factory showed that the adhesion of pre treated copper foil can reach 0.8N/mm, which is twice that of untreated copper foil, and copper detachment is less likely to occur when bent.

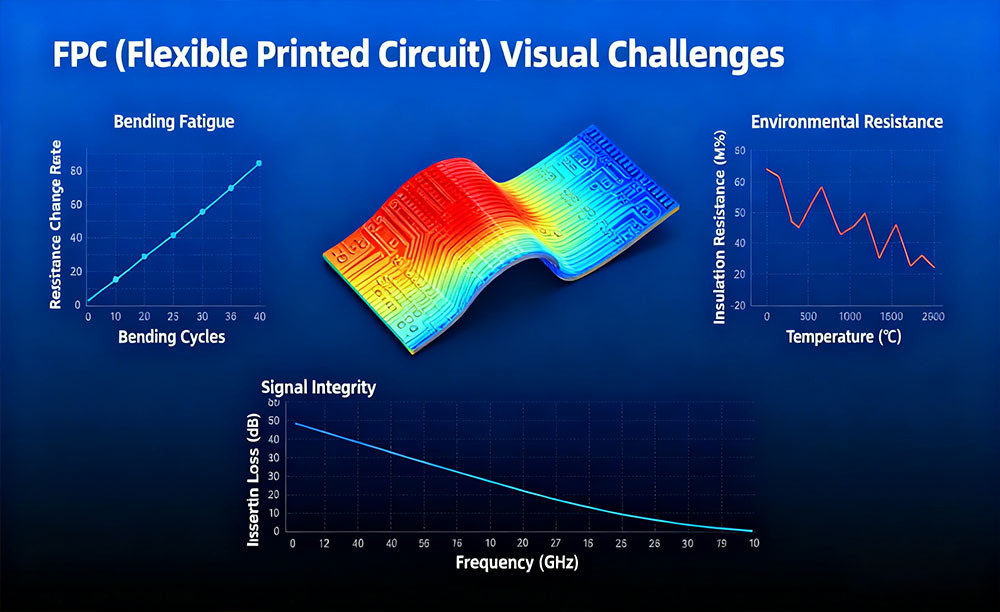

The manufacturing process of FPC is an art of balancing flexibility and rigidity, which not only allows the circuit board to bend like paper, but also ensures the conductivity and reliability of the circuit. With the development of wearable devices, flexible displays, and other fields, the manufacturing process of FPC will continue to advance towards thinner (thickness<0.05mm) and more bending resistant (over 500000 times) directions. In the future, we may see circuits woven like fabric, making electronic devices truly ubiquitous.

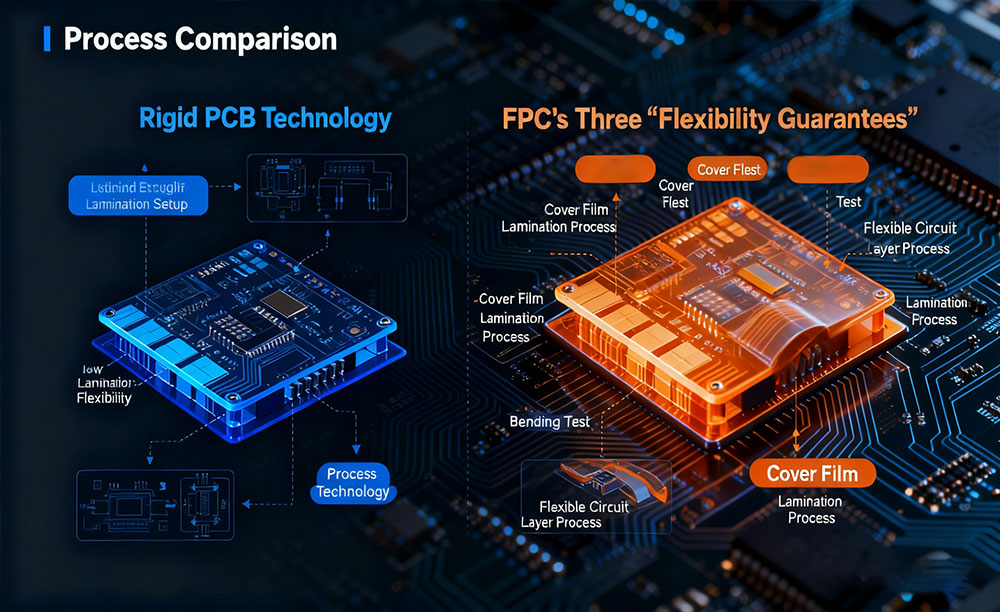

In the watch straps of foldable phones and smartwatches, there is a type of circuit board that can bend like paper - flexible printed circuit board (FPC). It can keep the circuit smooth through repeated folding and bending, not by magic, but by special materials and precise manufacturing processes. From material selection to final molding, every step of FPC needs to balance "flexibility" and "conductivity", which is much more difficult to manufacture than ordinary rigid PCBs.

Against the backdrop of the continuously increasing demand for data transmission speed in AI robots, the performance of flexible copper-clad laminate (FCCL), as the core substrate of soft hard junction board (R-FPC), directly determines the transmission quality of high-frequency signals between the robot's "brain" and "limbs", becoming a key carrier to break through the bottleneck of signal delay.

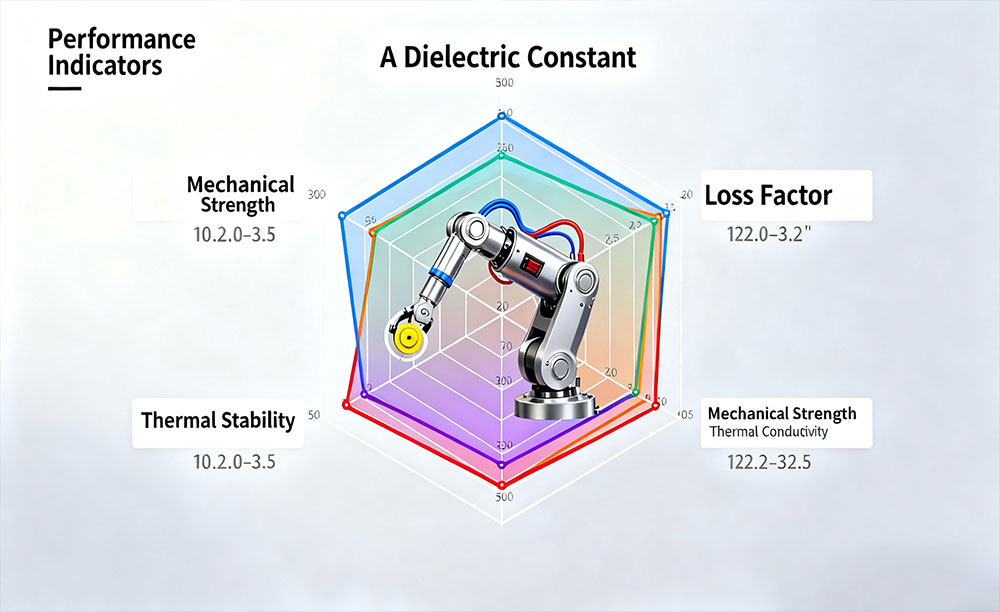

For AI robots using soft hard composite boards, the performance of high-frequency FCCL is not simply "high" in a single dimension, but needs to be deeply adapted to the application scenarios and work environments of the robot. The selection of its core performance indicators directly affects the overall performance of the soft hard composite board.