With the development of AI robots towards "miniaturization and high integration", the limitations of traditional high-frequency FCCL in thickness, weight, and functional integration are gradually emerging. The industry is promoting deep matching between high-frequency FCCL and robot design requirements through three major technological innovations.

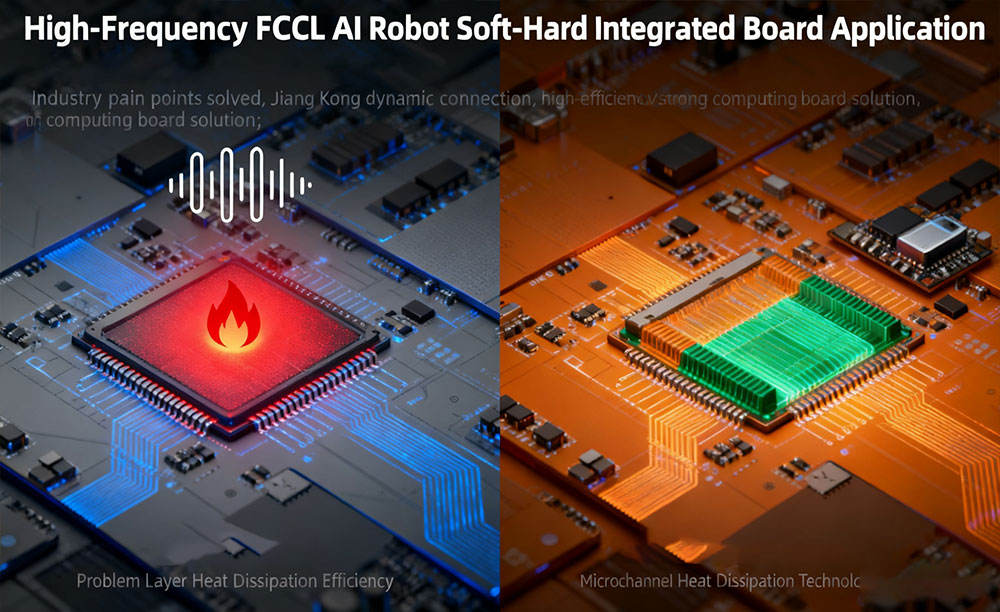

Although high-frequency FCCL has broad application prospects in the field of AI robots, it still faces three major pain points: high cost, insufficient reliability, and difficult process adaptation. The industry is gradually finding solutions through technological innovation and industry chain collaboration.

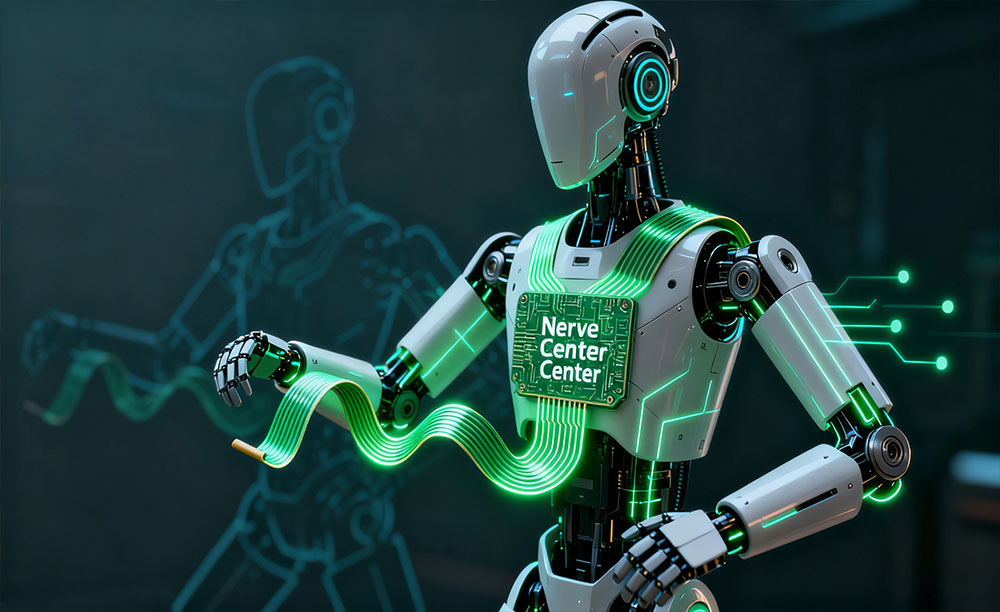

In the process of AI robots evolving towards miniaturization and high mobility, traditional rigid circuit boards are becoming a key bottleneck in their mobility. Flexible printed circuit boards (FPCs) have successfully overcome this limitation with their core characteristics of being flexible and thin, becoming the "nerve center" for moving parts such as robot joints and robotic arms.