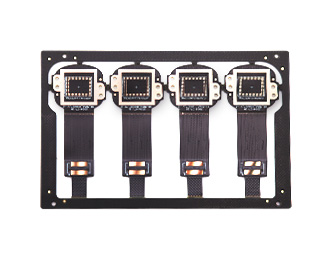

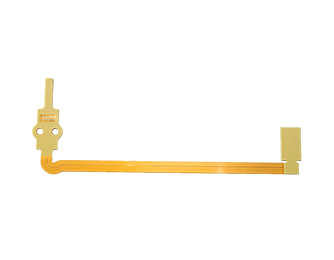

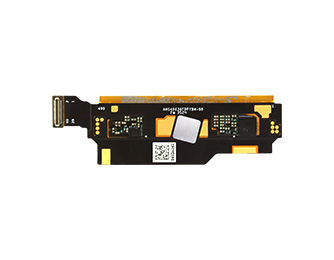

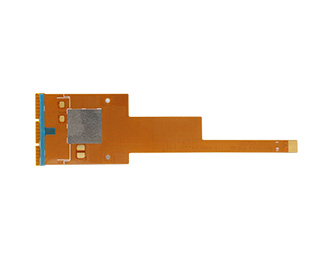

In the watch straps of foldable phones and smartwatches, there is a type of circuit board that can bend like paper - flexible printed circuit board (FPC). It can keep the circuit smooth through repeated folding and bending, not by magic, but by special materials and precise manufacturing processes. From material selection to final molding, every step of FPC needs to balance "flexibility" and "conductivity", which is much more difficult to manufacture than ordinary rigid PCBs.

When AI robots need to perform complex calculations and flexible actions simultaneously, a single ri

Listed below are printed circuit board assembly and PCB manufacturing capabilities. with everything you need to...

Listed below are printed circuit board assembly and PCB manufacturing capabilities. with everything you need to...

Listed below are printed circuit board assembly and PCB manufacturing capabilities. with everything you need to...

Listed below are printed circuit board assembly and PCB manufacturing capabilities. with everything you need to...

Listed below are printed circuit board assembly and PCB manufacturing capabilities. with everything you need to...